What is a humidification materials sheet?

It is a sheet used for evaporative humidifiers that vaporize water as room temperature. By this, passing air is humidified and changed into clean and moist air, then it improves room environment.

We have developed sheets with superior water absorption property. By applying corrugate processing (three-dimensional corrugating processing) to them and making them into elements, passing air contacts them efficiently and improves humidification efficiency.

Also, humidification materials sheets for air conditioners have features that they excel not only in water absorption property, but also in water retention property, hot water resistance and antibacterial property. Even after repeating drying and humidification, they can be used for a long time.

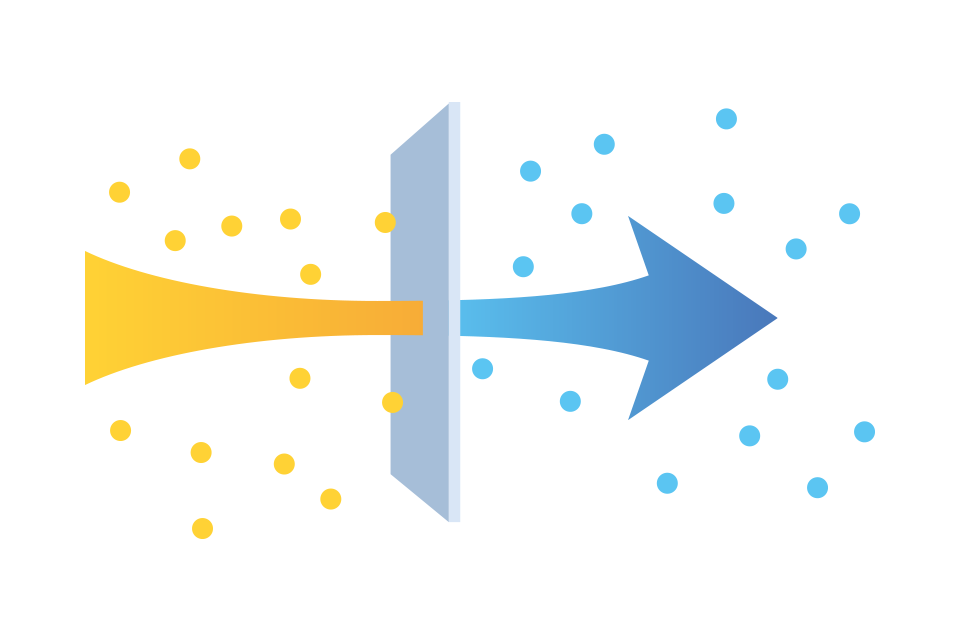

Principle and Characteristics of vaporization system

Air

Humidification air

Water supply

Humidification sheets

Water discharge

We take advantage of the principle that washed laundry dries by passing air (ventilation).

When air passes through a humidification materials sheet wet with water, moisture in the sheet evaporates and the absolute humidity in the room increases. Also as heat is taken by water vaporization phenomenon, evaporative cooling occurs in the air passing through a humidification materials sheet and the temperature in the room goes down.

Function and Usage application

Function and achievement

Evaporative humidifier Material sheet (for humidification)

- Function

- Formability (corrugate processing), water absorption, water resistance, antibacterial property, heat resistance.

- Achievements

- Humidifier manufacturers → Delivery of water absorbing sheets (corrugate processed products) for over 25 years.

End users → Domestic major liquid crystal panel factories, plasma factories, LED chemical factories, electric components factories, car paint booths, cosmetics factories, mushroom growing greenhouses, vegetable sale booths, air conditioning in hotels and hospitals, and so on.

Material sheets for cooling

- Achievements

- Cooling effect for the purpose of improving the power-generating (combustion) efficiency of a thermal power station has been confirmed.

Side benefits of evaporative humidification material sheets

Cooling effect

evaporation, as the vaporization heat (evaporative latent heat) is taken by water vapor, the temperature of humidified air goes down in response to humidification.

Evaporative cooling occurs, so it is used for cooling fans.

Deodorizing effect

If passing air contains water-soluble gas, it is absorbed inside the element (gas elimination)

by a water film and the amount of absorbed gas odor (bad odor) can be reduced.